Industrial maintenance

Our team specialized in industrial maintenance mission, can be present on your site, your workplace to do:

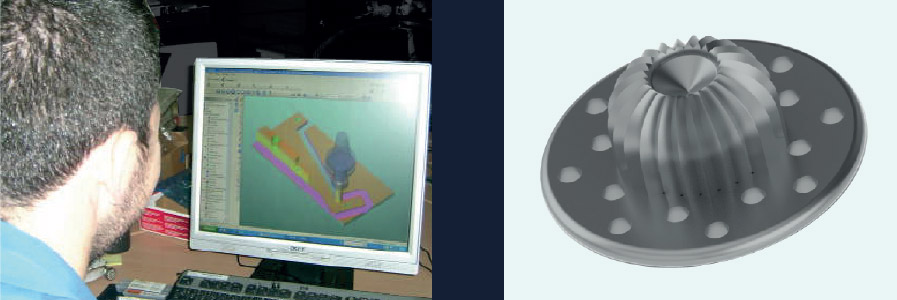

- Propositions concerning repaired solution and implementation following your specifications and diagnosis done on the site

- Assembly , re-assembly and clarification of revised mechanical system

- Operations of urgent repair, preventive and curative maintenance after wear of components or untimely degradation

- Realization of parts and sub-assembly worked to do alternative

We have our equipment for all on-site operations and our teams are trained in the latest safety rules.

Our organization and the breadth of know-how of the entities in our group make it possible to take over the most complex operations within the agreed timeframes.